Improving the quality of finished products

Optimize your products with uniform, precise grease application.

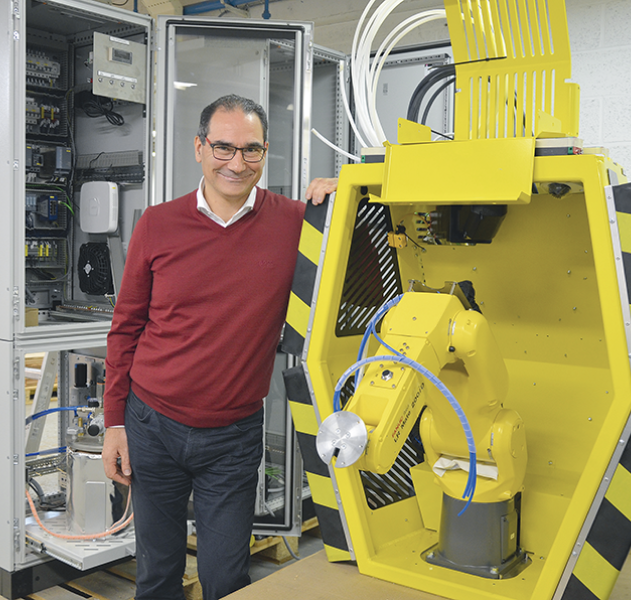

Our swabbing robots enable our customers to optimize their operational efficiency, maintain a consistently high level of quality and improve operator safety, while reducing their impact on the environment.

Manual mould lubrication in container glass production presents many challenges and inefficiencies. This time-consuming method leads to frequent stoppages, considerably reducing your productivity. In addition, the uneven application of grease leads to uneven mould wear, affecting not only the quality of your finished products but also the lifespan of your equipment, increasing production defects and maintenance costs.

This method also contributes to excessive consumption of your resources, generating significant waste. In addition, manual lubrication exposes your operators to significant risks, such as burns, cuts and exposure to products that are harmful to their health. These arduous working conditions, combined with high staff turnover, lead to additional costs and undermine the continuity and efficiency of your production.

Explore all the advantages of Socabelec swabbing robots dedicated to the glass container industry. Download our 2024 brochure to find out how you can increase productivity, maintain optimum quality, enhance operator safety and reduce your environmental footprint.

Optimize your products with uniform, precise grease application.

Reduce downtime to maximize your production cycles.

Protect your teams by eliminating the risks associated with manual greasing.

Reduce the waste of resources and adopt a more sustainable production approach.

Choose the Socabelec swabbing robot to optimize your operations and boost customer satisfaction. By automating the greasing of moulds, you ensure uniform application, which improves the quality of your finished products. Better quality products mean fewer defects and more confidence from your customers, reducing returns and increasing loyalty. What’s more, our robots reduce downtime, increase your production capacity and lower your operating costs, while ensuring the safety of your operators and responsible management of resources.

Our swabbing robots eliminate production downtime, optimizing the efficiency of your IS production lines (+2% min. productivity).

The continuous operation of your IS machines helps to maintain optimum thermal stability of your glass, enabling you to considerably reduce your bottle rejects.

Our robots use precise quantities of oil, making more efficient use of your resources.

By applying precise quantities of oil, our robots enable you to make significant savings on your production costs.

The gentle lubrication provided by our robots helps extend the life of your moulds, reducing your replacement and maintenance costs.

By extending the life of your moulds, you reduce the number of interventions on your IS machines. This translates into a significant reduction in your maintenance and replacement costs.

By automating the mould lubrication operation, companies reduce their dependence on human labour.

Reducing the workforce through automation immediately translates into significant savings on your HR budgets (recruitment, training, turnover, etc.).

Thanks to the precise and uniform lubrication of your moulds, our robots guarantee the consistent quality of your glass containers, ensuring high production standards.

Consistent quality in your glass containers significantly reduces the risk of defects, which translates into a significant reduction in your bottle rejects.

By eliminating reliance on human operators, our robots ensure accurate and consistent execution of the swabbing operation, minimizing the risk of errors and inconsistencies.

Thanks to their ability to reduce the risk of errors or inconsistencies, our robots guarantee consistent quality, ensuring results that meet your production requirements.

Our swabbing robots are designed to reduce the risk of accidents by integrating detection systems, remote controls and thermal protection. These innovations ensure the safety of operators in a demanding and intense production environment.

Robots are equipped with sensors that detect the presence of operators or objects in the work area. If detected, the robot automatically stops, preventing any risk of accident.

Remote control of the robot reduces the risk of operator exposure to hazardous areas. Process automation eliminates the need for human intervention, thus reducing accidents.

Our robots feature thermal protection to prevent excessive heat from compromising operator safety or damaging critical robot components.

Visual and audible warning systems inform operators of potential hazards or anomalies, enabling them to keep their distance from danger zones.

Our swabbing robots comply with the most stringent safety and hygiene standards, thanks to advanced filtration systems, resistant materials and precise lubrication control.

Filtration systems ensure that lubricants are free from contaminants. Containment prevents spills, ensuring a clean working environment.

Robot components are made from corrosion-resistant materials designed for easy cleaning, reducing the risk of contamination.

Precise lubricant dosing avoids any excess that could lead to spills or contamination, while ensuring efficient lubrication.

Robots incorporate systems that comply with ISO 13849-1 standards, including continuous diagnostics and redundant safety circuits, guaranteeing safe operation.

Reduce waste by optimizing the amount of oil used, while maintaining efficient production and optimum quality.

Reduce your ecological footprint by integrating automated processes that consume fewer resources.

Free your operators from repetitive tasks and redirect them to higher value-added roles.

LoreImprove employee satisfaction by involving them in more rewarding and stimulating assignments.

Explore all the advantages of Socabelec swabbing robots dedicated to the glass container industry. Download our 2024 brochure to find out how you can increase productivity, maintain optimum quality, enhance operator safety and reduce your environmental footprint.

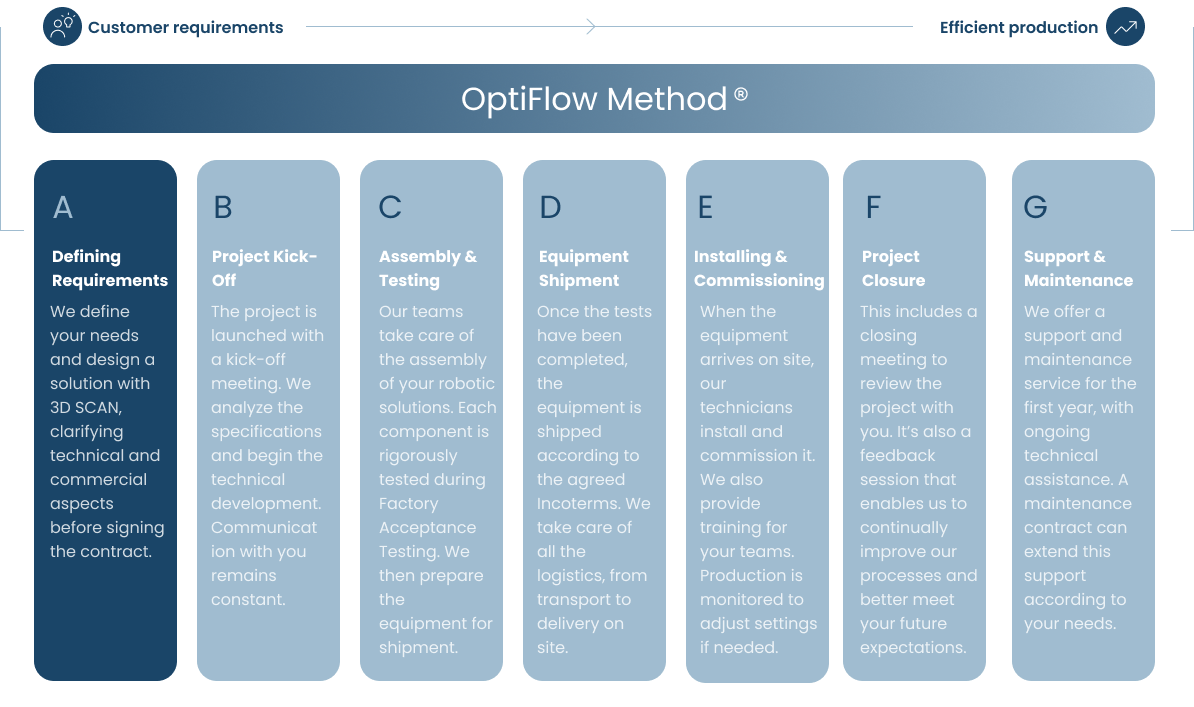

At Socabelec, every project is unique. Thanks to our OptiFlow Method® , we design tailor-made robotic solutions, perfectly adapted to the specific constraints of each customer and each machine. OptiFlow Method® takes into account your budget, deadlines and technical requirements to ensure the success of your project. From initial contact to on-site training, we’re with you every step of the way to guarantee optimum results, with no nasty surprises.

With over 50 years' experience in the field, Socabelec is a leader in automation and industrial robotics.

Our solutions are already in action at more than 31 sites worldwide, improving their operational efficiency every day.

With more than 35 customers worldwide, Socabelec is the trusted partner for customised, high-performance robotic solutions.

Explore all the advantages of Socabelec swabbing robots dedicated to the glass container industry. Download our 2024 brochure to find out how you can increase productivity, maintain optimum quality, enhance operator safety and reduce your environmental footprint.