-

- Veri Marco

- Publié le 14/10/2024

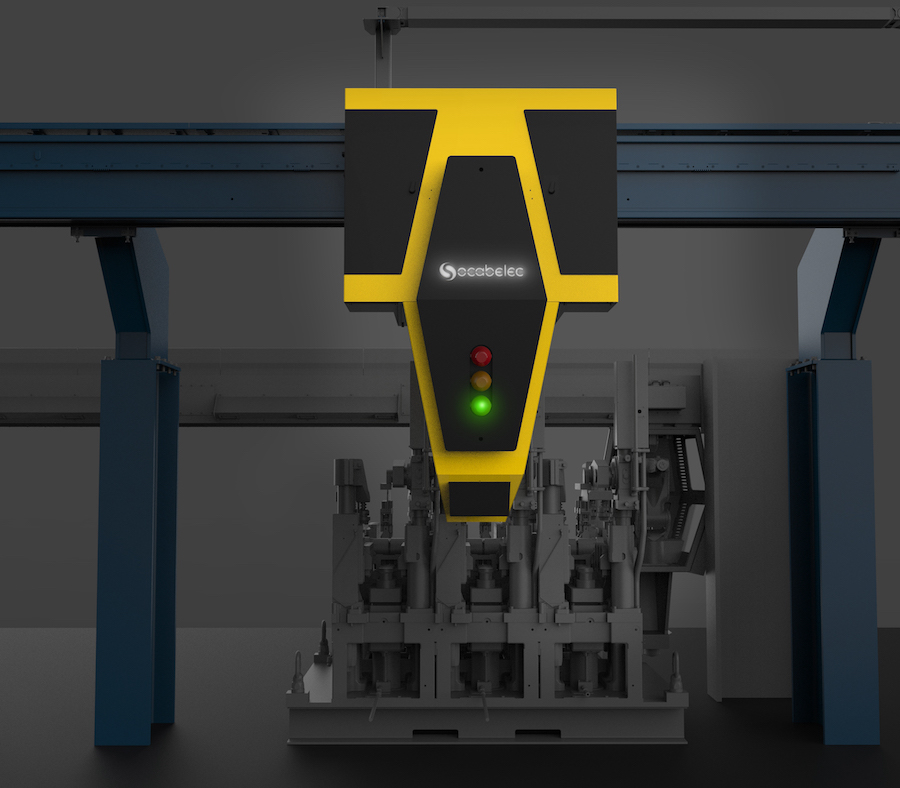

In the competitive world of glass container manufacturing, efficiency, safety, and quality are critical to success. Socabelec, a leader in robotic automation for the glass container production industry, is proud to introduce the RomoSwab—a cutting-edge robot designed to automate the mold lubrication process on the blow side of IS machines.

This game-changing solution, launching in October 2024, tackles long-standing issues with manual swabbing and delivers unprecedented levels of productivity and safety to glass manufacturing operations.

Furthermore, the RomoSwab supports the industry’s drive toward sustainability, reducing waste and optimizing resource use.

For years, glass container manufacturers have relied on manual lubrication methods that expose workers to safety risks, cause frequent production stoppages, and lead to inconsistencies in product quality.

These challenges are particularly prevalent in the high-demand sectors of glass container production for cosmetics, pharmaceuticals, beverages, and eco-friendly glass containers.

The RomoSwab completely automates the lubrication process, eliminating the need for manual intervention and enabling manufacturers to increase production efficiency while improving worker safety.

This innovative solution ensures uniform lubricant application to molds, which reduces product defects, boosts quality, and contributes to a more environmentally responsible manufacturing process.

The RomoSwab is engineered to fit seamlessly into existing IS machines used in glass container manufacturing.

It leverages the advanced capabilities of the FANUC LR Mate robot, offering precise, repeatable lubrication with a positioning accuracy of ±0.02 mm. This precision ensures that every mold receives the exact amount of lubricant required for optimal performance, leading to a consistent product output and minimizing waste, which aligns with the industry’s goals for sustainable production.

Technical specifications:

Thanks to its plug-and-play design, the RomoSwab integrates effortlessly into current glass container production lines, minimizing downtime during implementation. This compatibility makes it a highly attractive option for glass container manufacturers looking to modernize their operations while also reducing their environmental footprint.

Frequent production stoppages for manual lubrication slow down the glass manufacturing process and reduce overall output.

With the RomoSwab, while the production must still stop for lubrication, an operator is no longer required. The RomoSwab can perform lubrication on the Blow Side while the Neckring cycle is running on the Blank Side, optimizing the downtime. When combined with the Swabbing Robot, this offers a comprehensive solution that fully automates lubrication on IS machines. This automation significantly boosts productivity and reduces the need for manual interventions.

Frequent production stoppages for manual lubrication slow down the glass manufacturing process and reduce overall output.

With the RomoSwab, lubrication is done continuously, without the need to halt the production line. This not only reduces costly downtime but also increases throughput, enabling glass container manufacturers to meet their production targets more efficiently. Additionally, continuous operation reduces energy consumption, further supporting sustainable manufacturing practices.

Inconsistent lubrication can result in defective glass containers, leading to product rejections and financial losses.

The RomoSwab ensures uniform lubricant application across all molds, reducing the risk of production defects. This consistency is especially important for manufacturers producing high-quality glass containers for sectors like perfumes, spirits, and pharmaceuticals, where precision and quality are paramount.

Reducing defects also leads to less waste, supporting the industry’s shift toward more sustainable production practices.

Manual lubrication often results in the overuse of lubricants, driving up operational costs and increasing environmental waste.

By automating the lubrication process, the RomoSwab ensures that the exact amount of lubricant is applied each time, reducing waste and saving costs.

This optimization not only lowers material expenses but also contributes to an eco-friendlier manufacturing process, in line with the growing emphasis on sustainability in the glass industry.

For companies involved in glass container production, RomoSwab represents a transformative solution.

Whether you’re producing glass for cosmetics, beverages, or pharmaceuticals, this robot allows you to modernize your production line and meet key business objectives such as improving safety, increasing productivity, reducing operational costs, and enhancing product quality.

At the same time, it helps manufacturers achieve their environmental goals, reducing waste and optimizing resource usage for a more sustainable future.

By automating key processes, the RomoSwab frees up your workforce to focus on higher-value tasks, such as quality assurance and process optimization. This shift not only improves worker satisfaction but also helps to drive innovation and continuous improvement in your glass container manufacturing processes.

Moreover, RomoSwab’s ability to optimize resources and reduce waste aligns perfectly with the industry’s push towards green manufacturing.

With its official release set for October 2024, now is the perfect time to explore how the RomoSwab can revolutionize your glass container manufacturing operations.

Socabelec’s expert team is available to provide product demonstrations and guide you through how the RomoSwab can be seamlessly integrated into your production line, delivering immediate improvements in efficiency, quality, safety, and sustainability.

Contact us today for more information or to schedule a demo ahead of the official launch at #glasstec2024. Don’t miss out on this opportunity to enhance your production capabilities and position your business at the forefront of sustainable glass manufacturing.

Download our 2024 brochure to find out how you can reduce defects, booss safety, and optimize your glass container production with seamless blow-side lubrication automation.

Veri Marco

CEO & Managing Director

Marco Veri has been leading Socabelec for over 27 years. Under his leadership, the company has become one of the leaders in robotic automation in the hollow glass industry, combining innovation, safety, and sustainability.